Mix-on-the-fly Spacer

Sanjel Energy’s patented VISWEEP DM IS (Dry Mix Invert Spacer) is an innovative spacer system which delivers improved cementing performance with reduced total well cost, project complexity and hazard exposure.

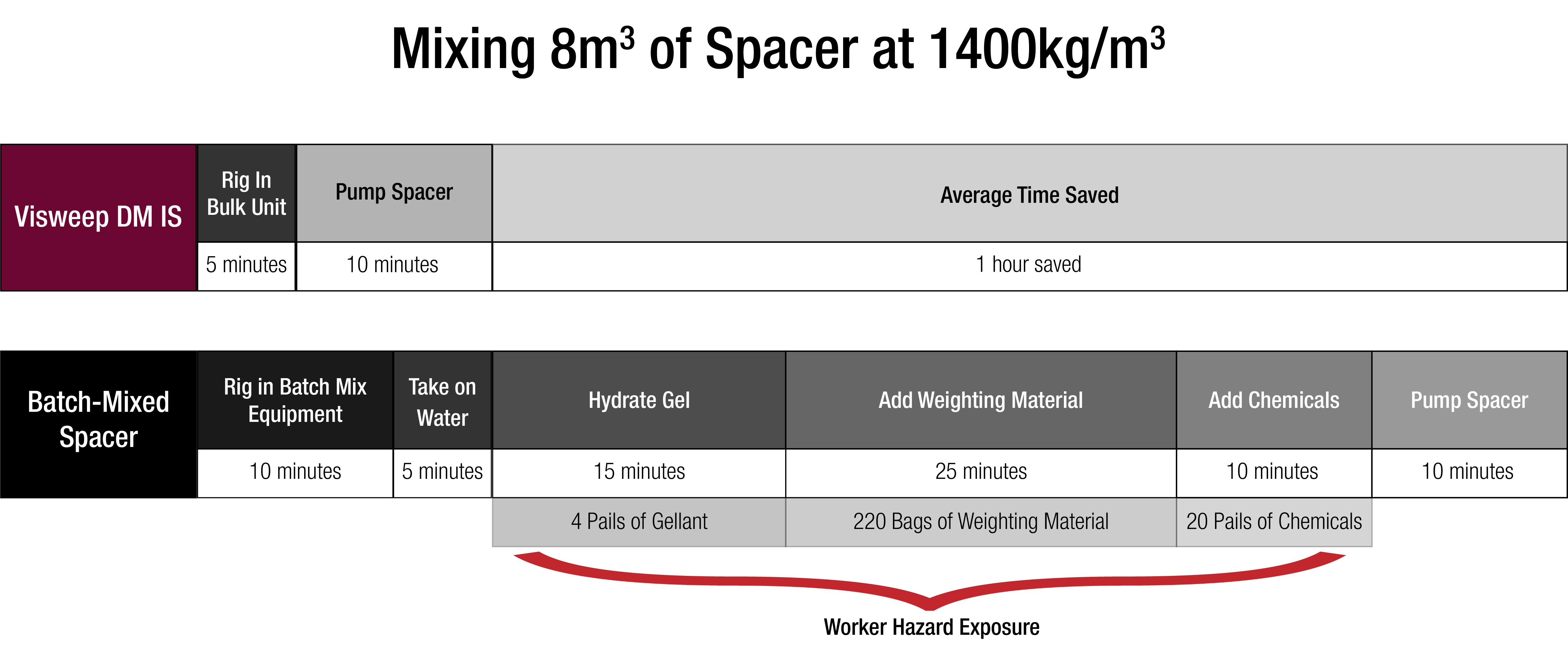

As drilling operators trial hole and casing size configurations to optimize drill speed and completion performance, the volume of spacers required to meet industry best practices are becoming larger than the tanks of cement pumping units. Sanjel Energy’s VISWEEP DM IS reduces the tanks, units and personnel required on location and is mixed in a matter of minutes, using the same equipment and procedures as mixing a cement slurry. All materials are blended off-site reducing the risk of chemical exposure and eliminating the time and risk of manually adding bags of weighting agents such as barite to increase density.

Applications

- Effectively displace all types of drilling fluids while water-wetting the casing, formation, and annulus

- Polymer types and loadings are easily optimized for rheology, stability and excellent displacement efficiency at any well temperature

- Additional performance additives such as salt, lost circulation reactive silicates, etc., can also be added as required per the job design

Features

- VISWEEP DM IS is a fully dry combination of oil-cleaning surfactants, rapid hydrating polymers and optimal weighting materials that converts casings and formations from oil-wet to water-wet for improved cement bonding

Benefits

- Optimize system rheology for ideal rheological hierarchy

- Improve cement bond

- Tailor spacer volume and density to well conditions

- Reduce rig time related to spacer preparation

- Rapidly and easily mix industry recommended spacer volumes for all well configurations

- Lower the risk of injury through eliminating repetitive strain movements

- Reduce chemical exposure to personnel